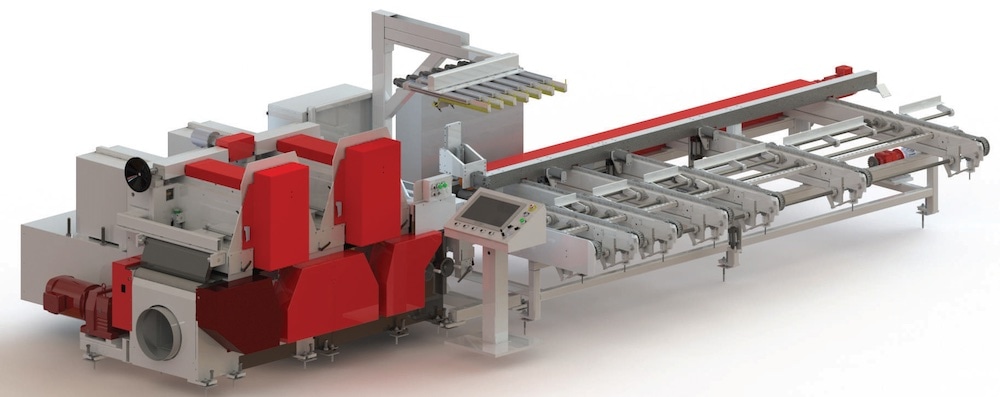

Model 5300 “Select-A-Rip”™ Rip Saw with Rip Navigator™ Trailblazer

Model 5300 “Select-A-Rip”™ Rip Sawwith Rip Navigator™ Trailblazer The 5300 with Trailblaze…

About Us

We’ve built our reputation by providing reliable, long-lasting machinery for cutting and processing since 1905. Always evolving and innovating, we combine practical understanding and experience with state-of-the-art engineering expertise. We won’t pigeonhole you into a standard solution. Instead, we’ll collaborate with you to find the best solution and bring it to life in our vertically integrated manufacturing facility, with more than 150,000 square feet of production space.

OUR MACHINES

Take a look at our high-quality standard rip saws, rip optimizing systems, dovetailers, tenoners, equalizers and sizing machines. Every standard machine is customizable, and we can also design and engineer a custom machine from your concept.

Model 5300 “Select-A-Rip”™ Rip Sawwith Rip Navigator™ Trailblazer The 5300 with Trailblaze…

The Model 110 Equalizer can be integrated with most moulders, creating a highly efficient…

Our Tenoners are designed for high production runs while simultaneously providing the flex…

Our Roll Feed Saw’s high-speed, high-yield hogging arbor options virtually eliminates edgi…

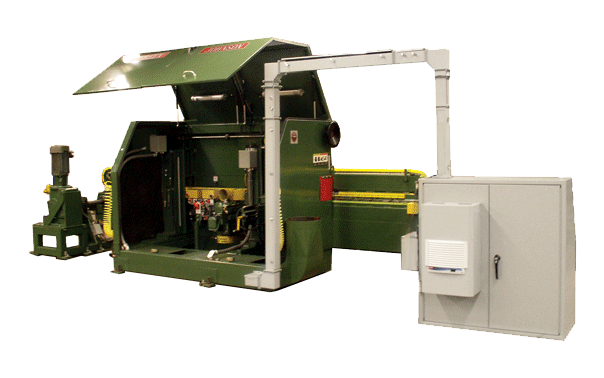

Our largest Rip Optimization system is the Scout; Equipped with infeed chains, board deale…

Now with NaviVision scanning, Mereen-Johnson provides multiple color cameras for single fa…

Feature the latest in technology advancements, ensuring improved consistency, accuracy, su…

Mereen-Johnson manufacturers a complete line of gang rip saw infeed systems from manual to…

With up to four moving saw blades, Select-Ripping has never been more affordable. Our 500…

Mereen-Johnson Multiple Rip Saws offer straight line precision gang ripping with glue join…

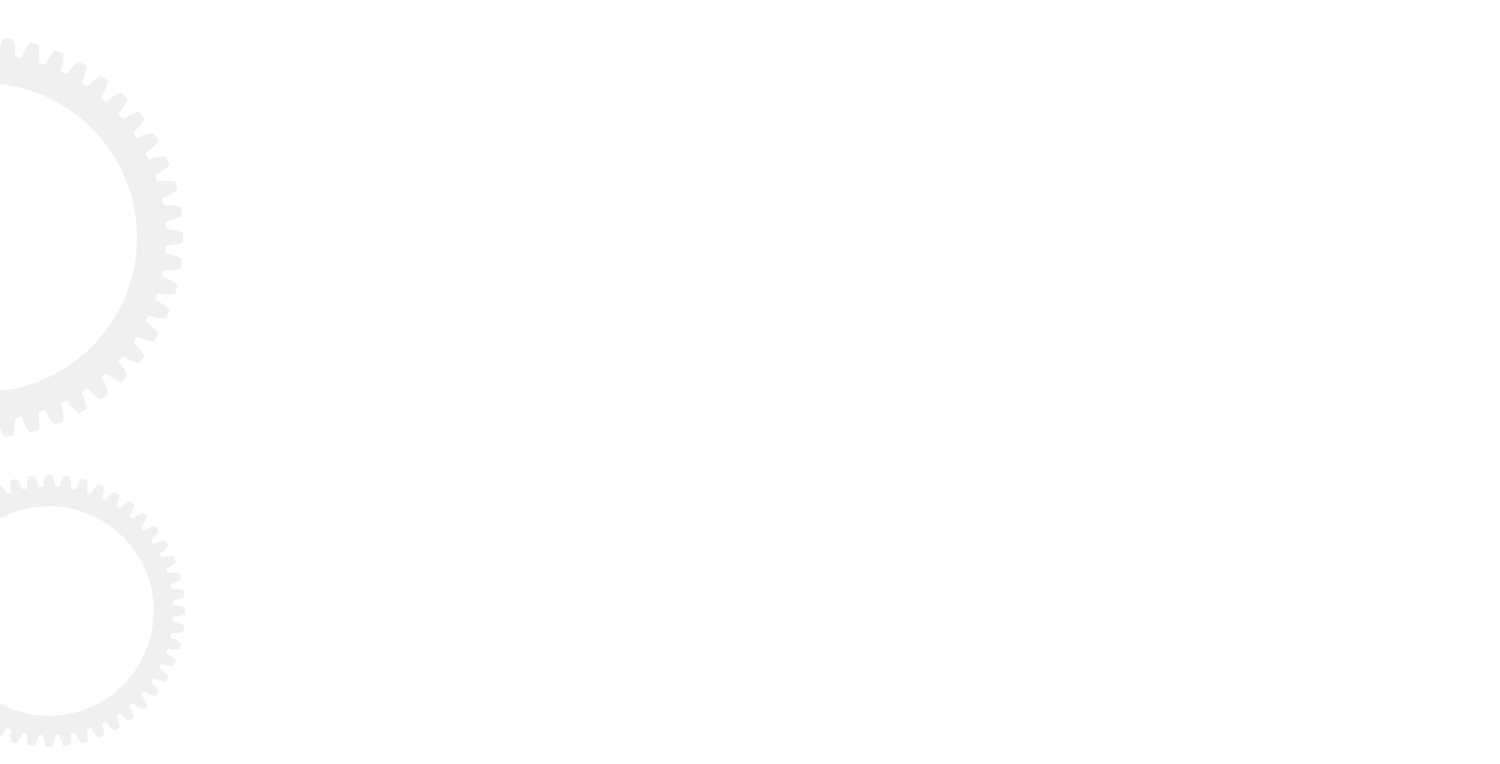

The Mereen-Johnson 300 Series rip saws offer all the quality, heavy-duty construction, and…

For big shop performance at a small shop price. 12″ arbor capacity with up to two inboard…

The Diehl Machines MR-90 is an undercutting roll feed gang rip saw. The roll feed design r…

Diehl’s Full-Sized Rip Saw, a machine with the speed and performance to meet the most dema…

The Diehl Machines SL-35 is are our mid-sized Rip Saw, an economically priced machine with…

Automation & Robotics

As efficiency, productivity, quality, staffing and safety challenges stack up, the need for automation solutions has become critical. We’ll transform your concept into reality with our internal design-build capabilities and advanced, technology-driven mechanical and electrical engineering expertise. This can include integrating robotic functionality for machine tending, sorting, stacking and destacking, to perform those tasks safely and efficiently when labor is hard to find.

Why Us

Vertically integrated manufacturing in the USA means we control every step of the process to deliver the performance and longevity that the industry has grown to expect from us.

Listening to your specific needs, we will adapt a standard machine or develop a fully custom solution, including automation and robotics, and manufacture it in-house.

Our state-of-the-art production space has room to build, test and prove large-scale design solutions. Design-build teams work together to make your custom concept a reality.

We will always support your machine. From training programs to replacement parts, schematics to software support, we’ve got you covered, remotely or onsite.

Diehl Machines

Producing a glue line cut that is second to none, straight-line rip saws from Diehl Machines set the industry standard. A division of Mereen-Johnson, Diehl Machines is dedicated to quality, accuracy and ease of operation.