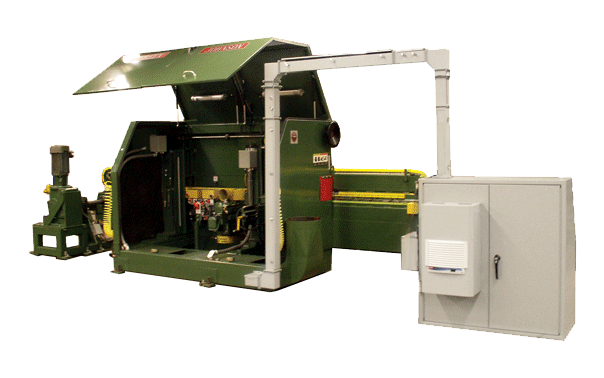

110 Equalizer

The Model 110 Equalizer can be integrated with most moulders, creating a highly efficient…

Mereen-Johnson manufacturers a complete line of gang rip saw infeed systems from manual to fully automated, integrated with Rip Navigator optimizing systems featuring the latest board scanning technology.

These systems will provide better feeding accuracy, detailed production and vendor reporting, improved lumber yield, higher profits and greater operator safety.

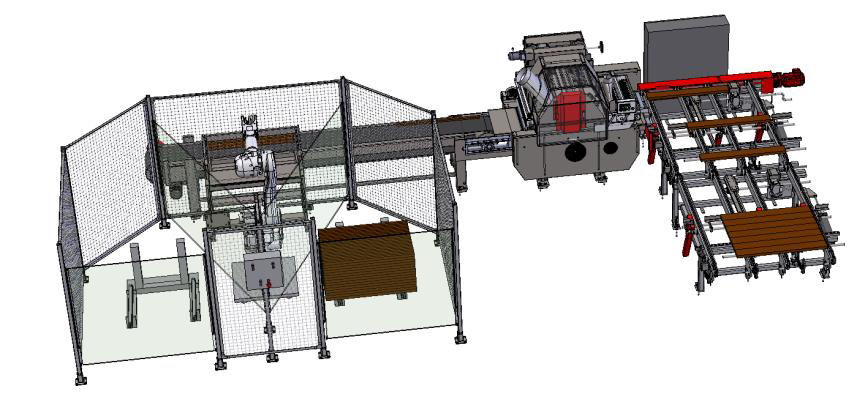

| Capacity | 24” arbor space, thickness to 2-1/2” using 14” dia. tooling, 30” min. length for glue joint accuracy. |

| Shifting Saw(s) | First arbor: Two shifting hoggers Second arbor: One to four shifting blade(s) in combination with fixed center blade. 1” min. width net rip between saws. |

| Arbor Drive | Direct drive 75 HP, 3600 RPM TEFC Mereen-Johnson saw arbor motor (no belts to tension or replace). |

| Feed Drive | 10 HP with variable frequency speed control, infinitely variable, 30’-235’ per minute. |

| Feed Bed | “Posi-Feed” friction feed bed of structural aluminum feed slats with replaceable steel backed rubber inserts carried on precision Double-Vee hardened steel feed chains and track. Oil mist lubrication of feed system with low oil level auto feed shut-off. |

| Hold Downs | Eight 4″ dia. air loaded press rolls. Air loaded traveling shoes provided for each shifting blade. |

| Anti-Kickbacks | Single lower, double upper infeed. Single upper outfeed. |

| Dust Collection | Two 10″ dia. and one 5″ dia. upper, two 5″ dia. lower, 7,440 total CFM required. |

| Electrical | Arranged for 3/60/230 or 460 volt power supply (other electrics available). |

| Shipping Information | Nominal 13′ by 6′ by 6′ shipping skid, 14,400 lbs, 6,550 kg. |

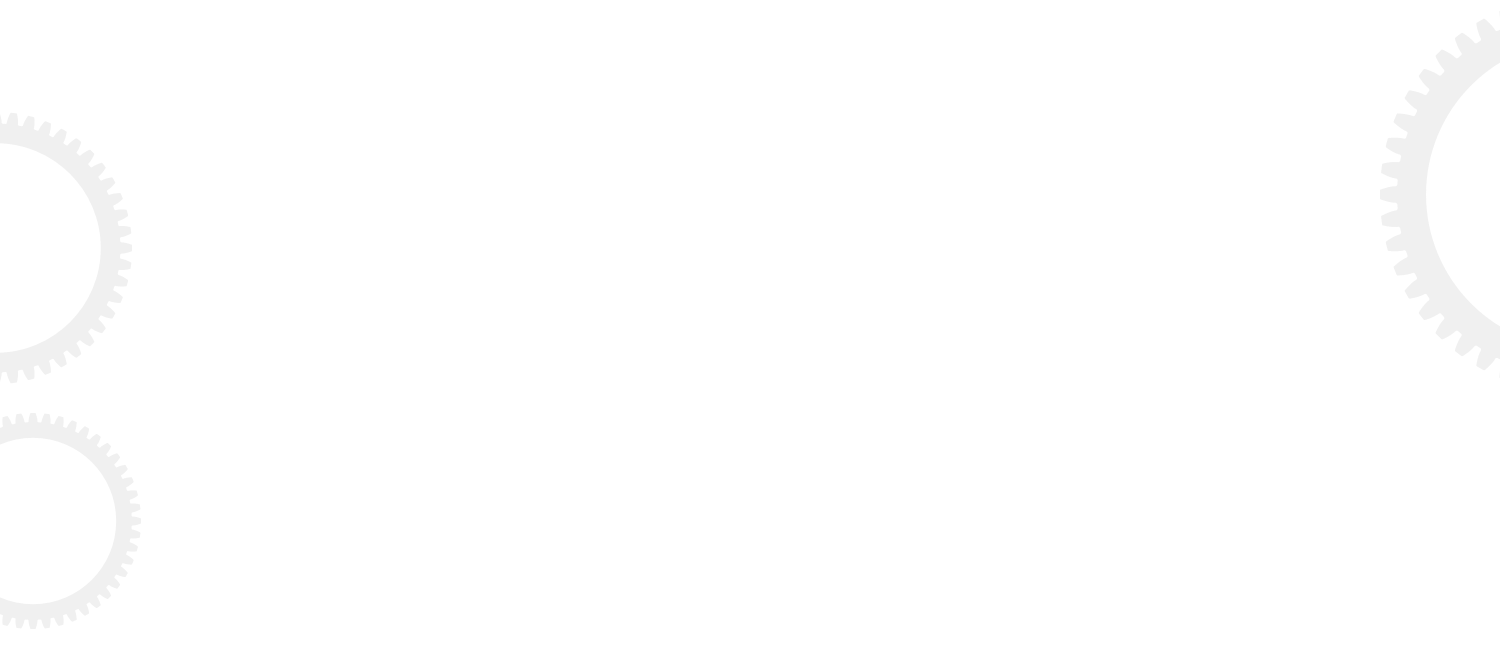

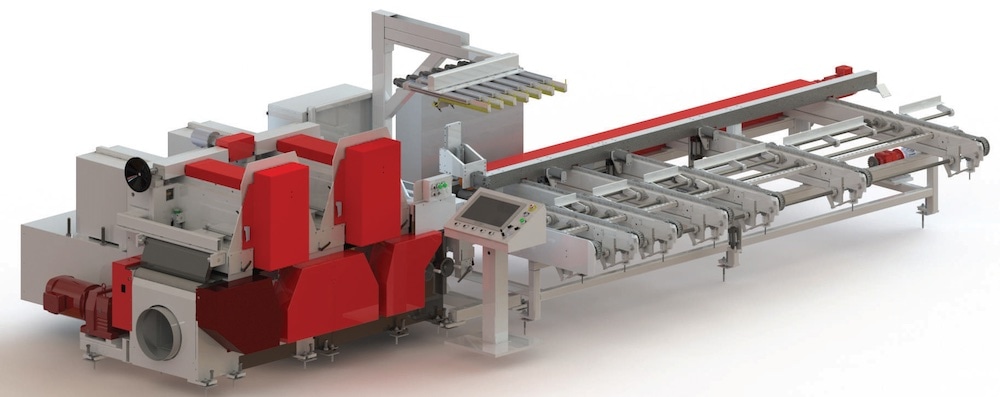

Automation & Robotics

Mereen-Johnson stands at the forefront of delivering cutting-edge automated handling solutions that will streamline your workforce and wood machinery assets. Our smart, automated handling solutions are meticulously crafted to enhance your machine throughput and efficacy while substantially trimming your labor expenses.

Our complete spectrum of services ranges from conceptualization and design of production lines to installation, personnel training and ongoing maintenance, and we cater to a wide array of client requirements, offering both standardized system solutions and fully personalized options to suit your specific needs.

Vertically integrated manufacturing in the USA means we control every step of the process to deliver the performance and longevity that the industry has grown to expect from us.

Listening to your specific needs, we will adapt a standard machine or develop a fully custom solution, including automation and robotics, and manufacture it in-house.

Our state-of-the-art production space has room to build, test and prove large-scale design solutions. Design-build teams work together to make your custom concept a reality.

We will always support your machine. From training programs to replacement parts, schematics to software support, we’ve got you covered, remotely or onsite.

The Model 110 Equalizer can be integrated with most moulders, creating a highly efficient…

Model 435 Series is a versatile line of machinery custom designed and manufactured for nea…

Mereen-Johnson’s CNC Dovetailers offer the quality construction, precision, reliability, a…

Feature the latest in technology advancements, ensuring improved consistency, accuracy, su…

For big shop performance at a small shop price. 12″ arbor capacity with up to two inboard…

The Mereen-Johnson 300 Series rip saws offer all the quality, heavy-duty construction, and…

Mereen-Johnson Multiple Rip Saws offer straight line precision gang ripping with glue join…

With up to four moving saw blades, Select-Ripping has never been more affordable. Our 500…

Perfect For High Production Operations, this machine is designed for high-production opera…

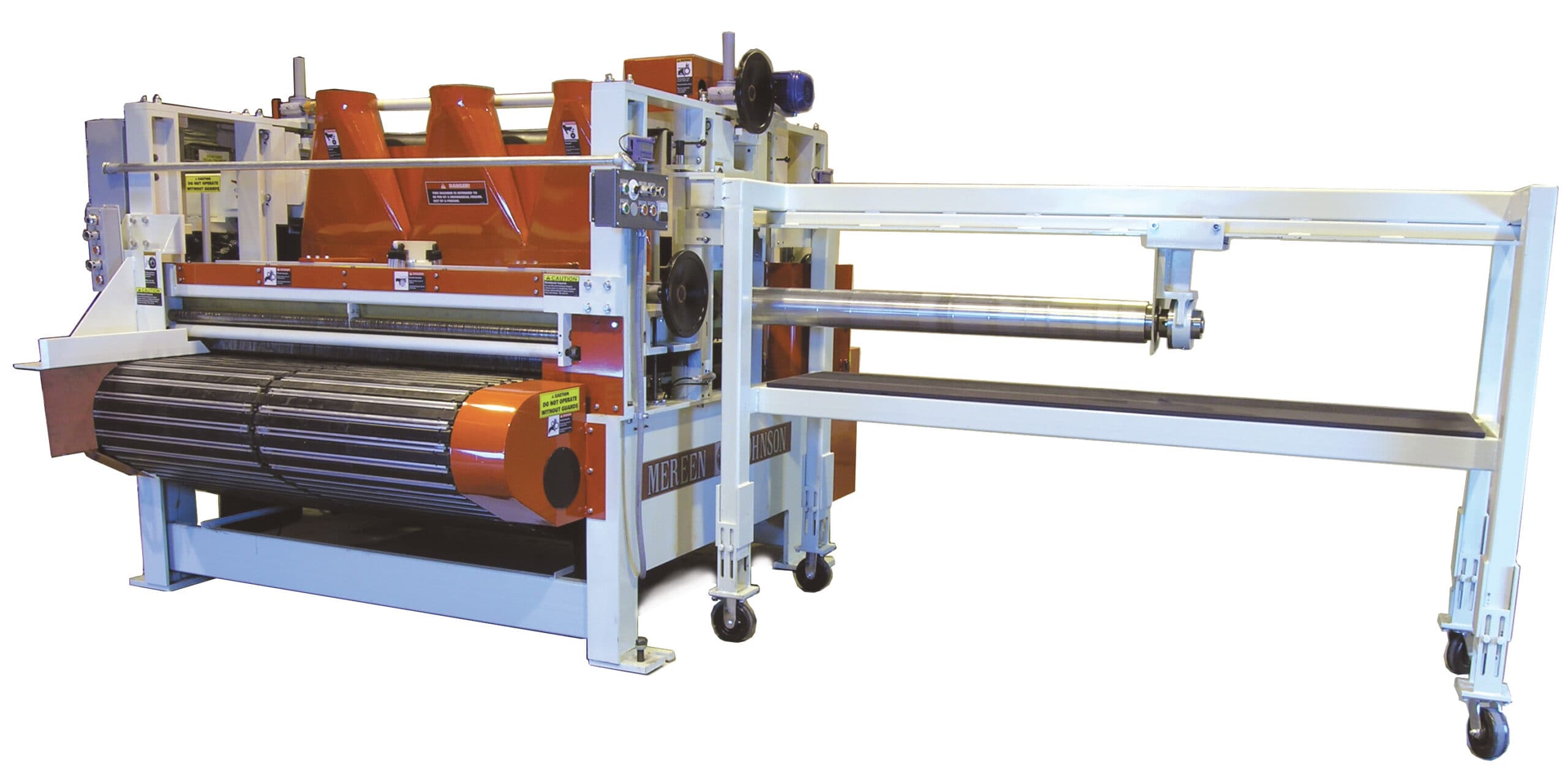

Now with NaviVision scanning, Mereen-Johnson provides multiple color cameras for single fa…

Our largest Rip Optimization system is the Scout; Equipped with infeed chains, board deale…

Our Roll Feed Saw’s high-speed, high-yield hogging arbor options virtually eliminates edgi…

Scout Loader is a fully automated feeder designed to directly offload deadpacked lumber fr…

Our Tenoners are designed for high production runs while simultaneously providing the flex…

The Diehl Machines MR-90 is an undercutting roll feed gang rip saw. The roll feed design r…

Diehl’s Full-Sized Rip Saw, a machine with the speed and performance to meet the most dema…

The Diehl Machines SL-35 is are our mid-sized Rip Saw, an economically priced machine with…