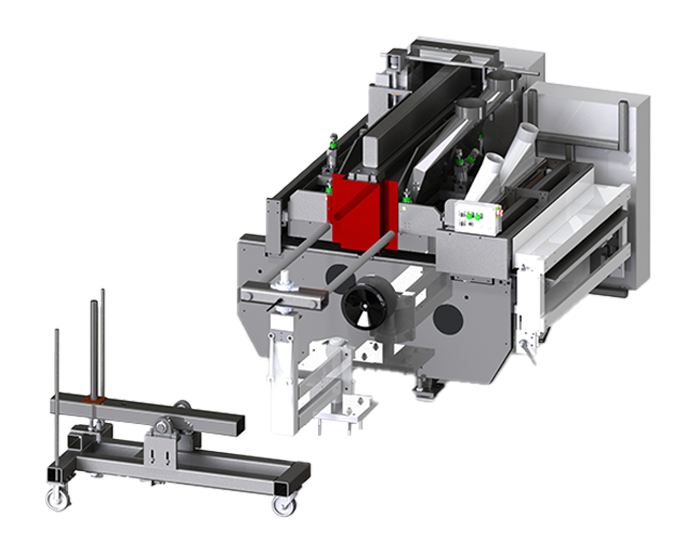

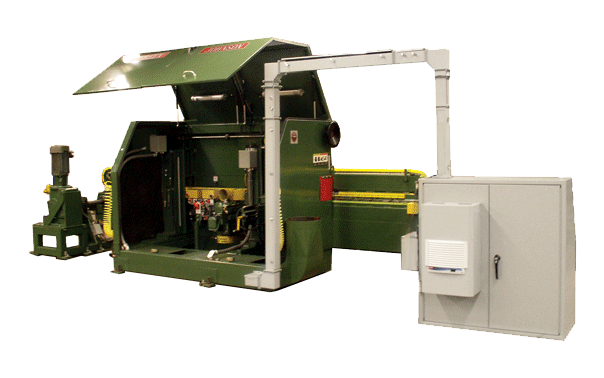

110 Equalizer

The Model 110 Equalizer can be integrated with most moulders, creating a highly efficient…

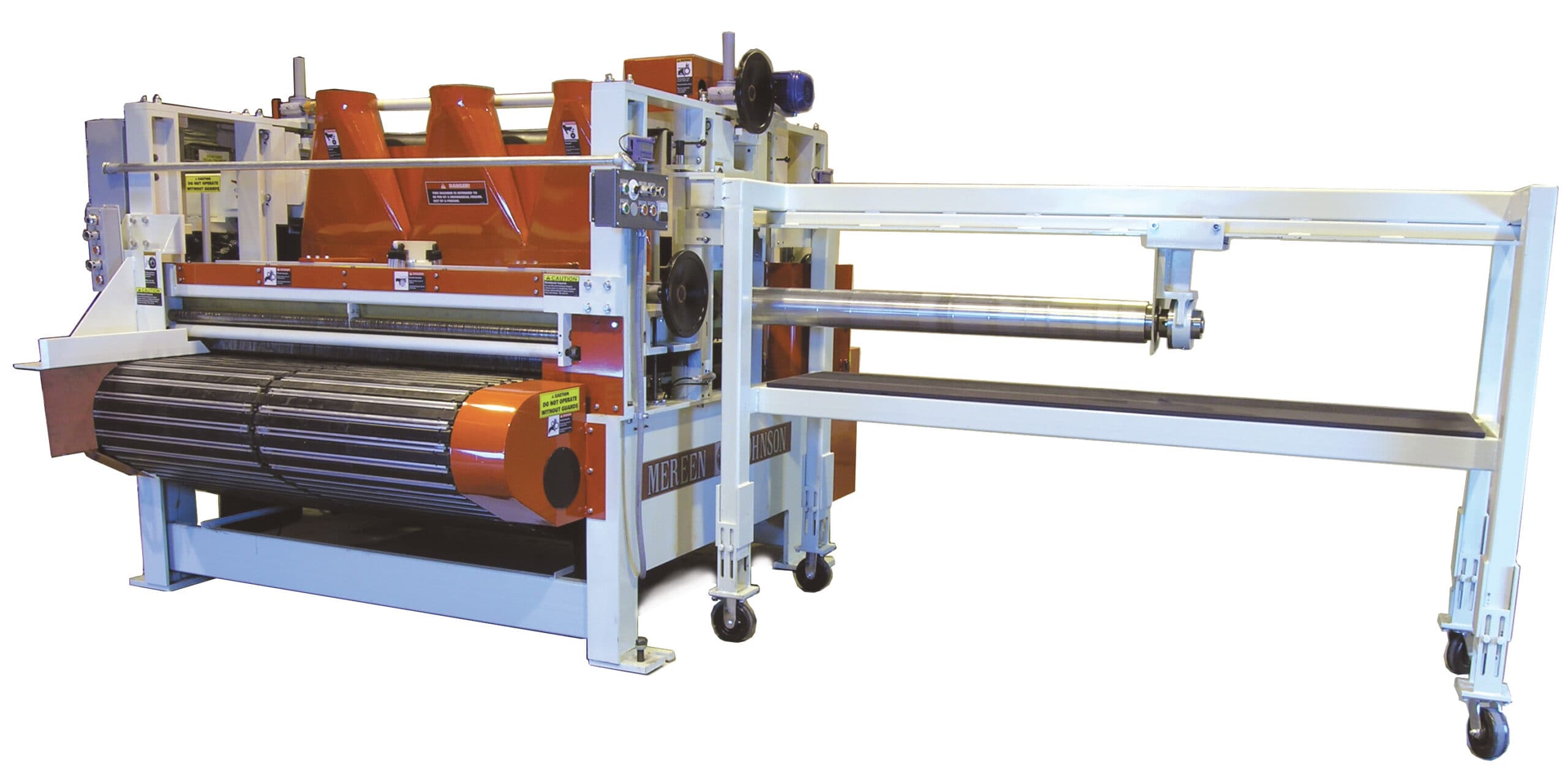

Mereen-Johnson Multiple Rip Saws offer straight line precision gang ripping with glue joint accuracy. Our “Posi-Feed” high friction feed bed provides optimum accuracy with no slippage using the same dependable “DOUBLE-VEE” feed chains utilized on Mereen-Johnson Tenoners. We currently have nearly 2,000 of these high production rip saws in use around the world meeting a wide range of applications.

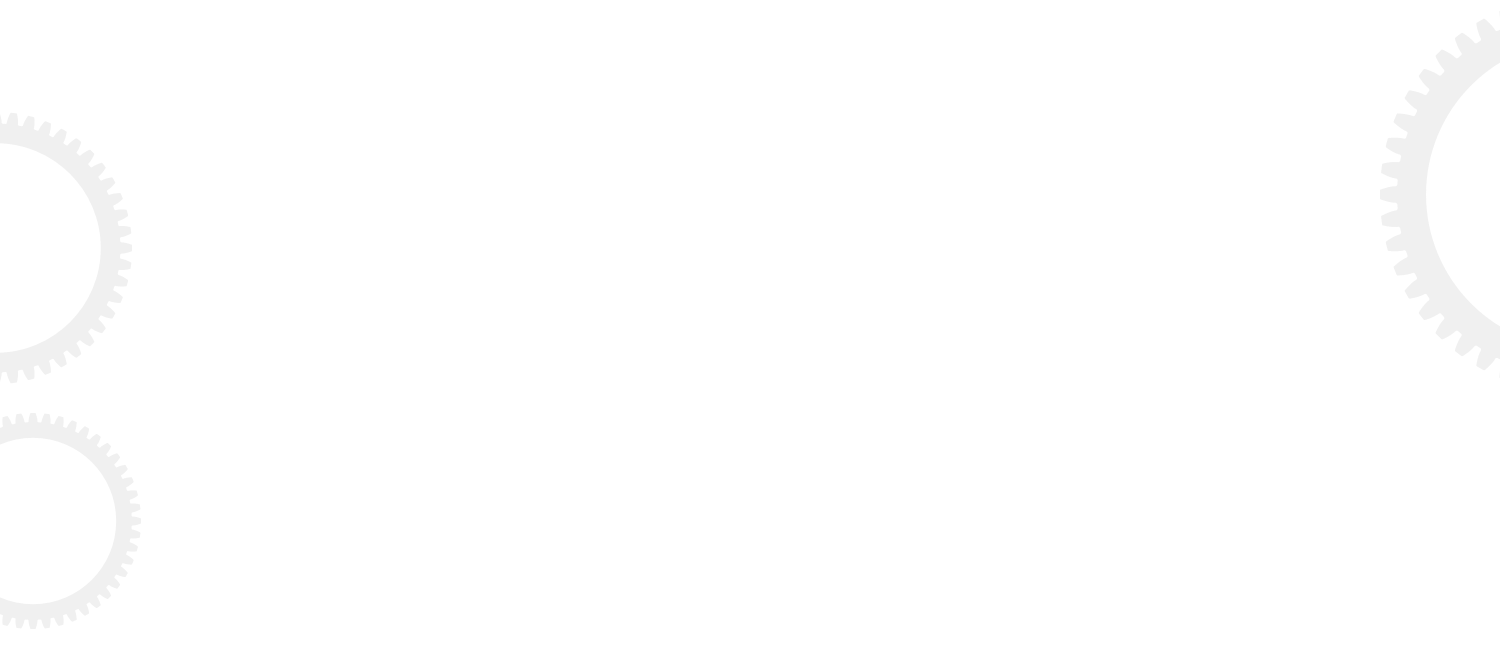

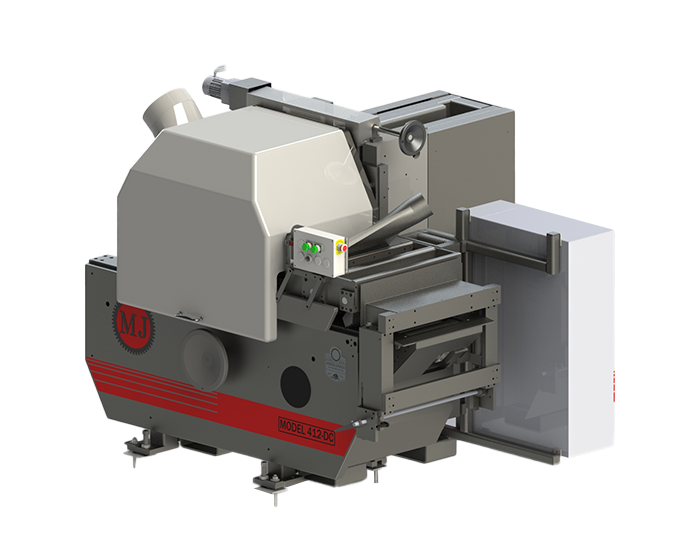

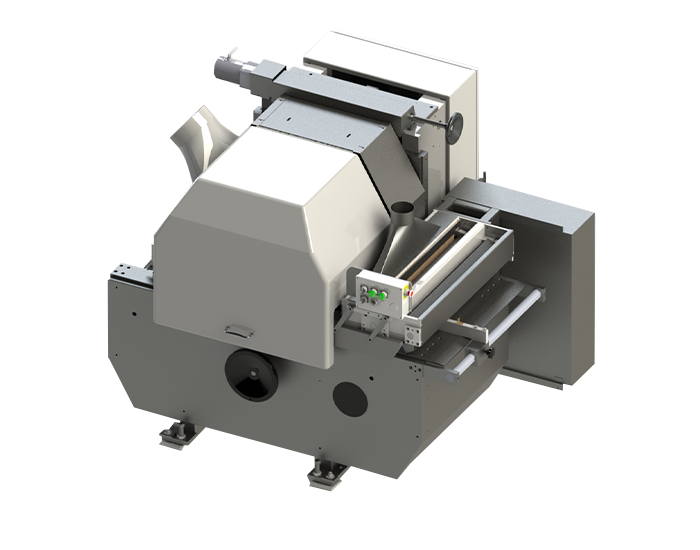

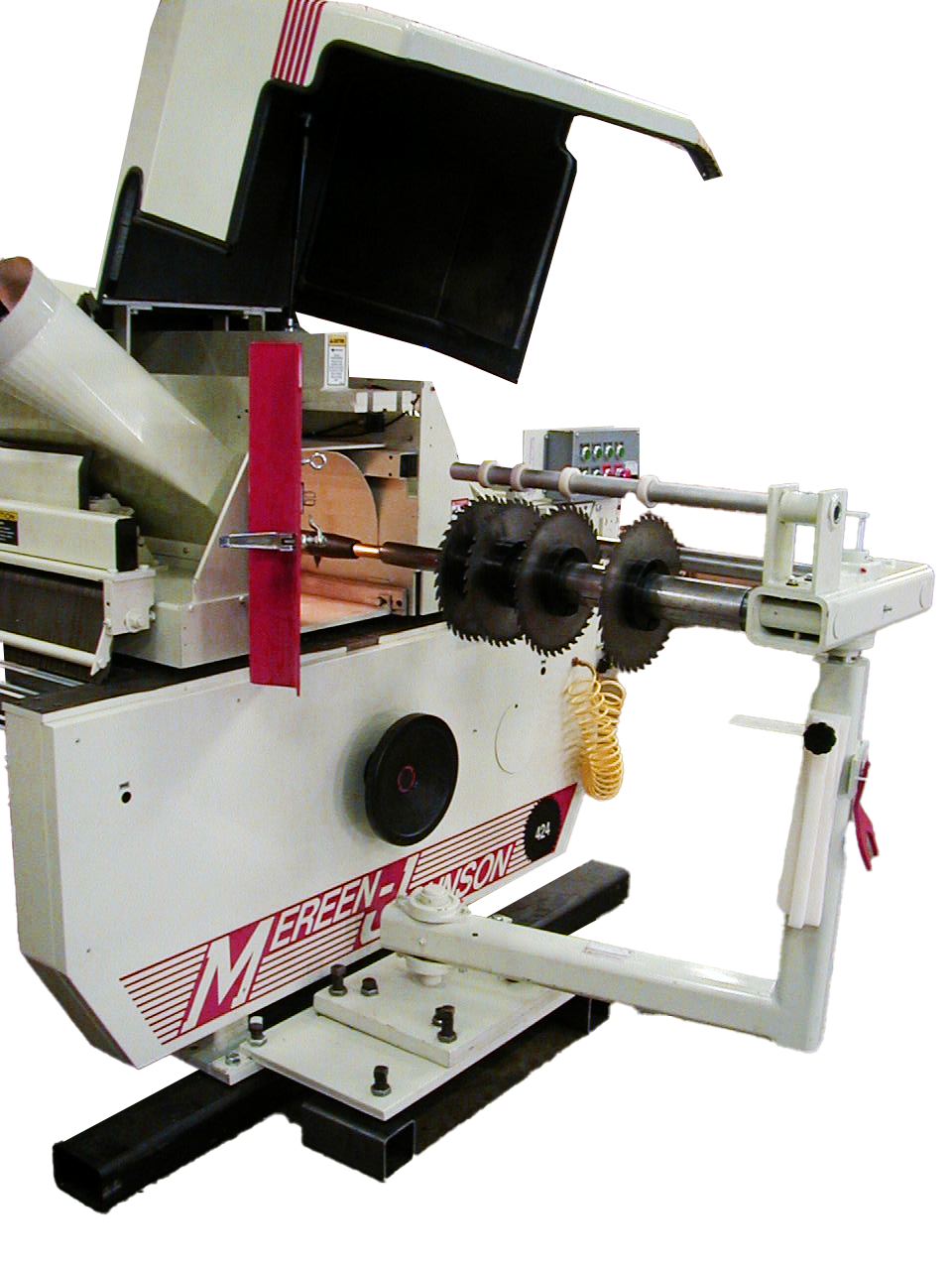

400 Series Multiple Rip

Straight, smooth, and square joints. Field proven glue joints using high frequency or clamp carrier systems.

Fixed arbor saws offer the greatest production capacity. Robust construction requiring minimal maintainence.

Minimum moulder allowance for increased yield. Width accuracy guarantee is +/-.005”.

Our Dip Chain Series rip saws are the “Standard of the Industry”. Available in 12”, 24”, 31” and 40” width capacities. Short Stock Models for cut first and recovery operations. Shifting Blade Models for maximum flexibility and yield recovery.

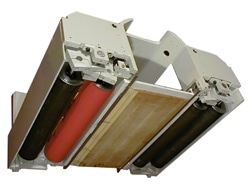

Full width air loaded roller hold downs and full width bed plate provide positive containment of material.

Available in smooth, rough, and short stock designs. Split pressure head designs are also available for side by side feed applications.

Dual, hardened steel “DOUBLE-VEE” feed chain and rail system. Oil mist lubrication with low level auto shut-off.

Exclusive hardended contoured “Quiet Cam” design for smooth operation. High strength aluminum slats with replaceable high friction steel backed rubber inserts.

Direct coupled feed drive with variable frequency speed control and overload protection. Feed rates 30-225′ per minute, higher rates optional.

Two rows of upper, and one row of lower fixed mounted anti-kickback fingers.

Zero rotation sensor, air actuated brake and door interlock, for safety and reduced down time.

Additional row of outfeed anti-kickback fingers.

Severe duty, direct drive arbor motor eliminates belt tensioning and maintainence.

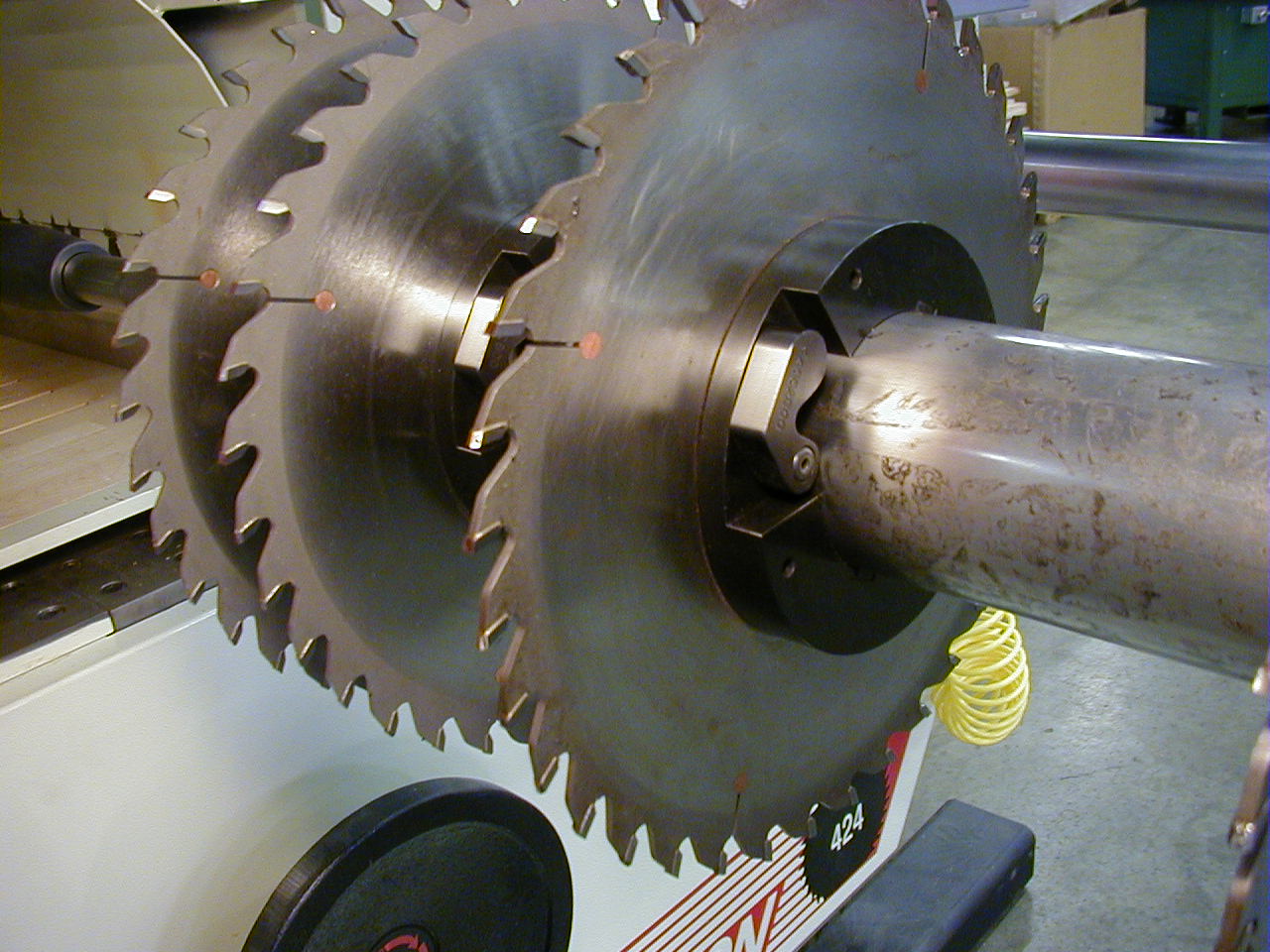

Heavy duty overbeam and cast aluminum slip-off end bearing.

lnfeed gauge bar facilitates laser light alignment.

Standard removabe sleeve and saw spacers provides high accuracy. Purchase a spare sleeve and spacer set allowing off line set-up for reduced down time.

Mereen-Johnson’s Twistlock fixed blade setting system provides fast and easy changeovers without saw spacers.

Optional tip-up cart assembly provides the preferred vertical set-up method. Cart and swing arm combination eliminates the need to manually left the sleeve.

Mereen-Johnson Rip Saws deliver consistent, reliable accuracy, whether ripping for moulding stock, dimension, edge glued panels, or re-ripping finger joint blanks for edge gluing.

Whether it’s ripping random width solid lumber or full sheets of MDF, Mereen-Johnson offers greater accuracy and wider capacity machines for better utilizing your raw materials, increasing your profit margins.

Precision components, S4S blanks for cabinet shops, re-ripping for salvage/reclaim operations. Increased accuracy means fewer rejects and higher value.

Ripping solid wood and re-ripping finger joint blanks for edge glued panels. Some saw manufacturers say their machines can provide glue joint accuracy. We guarantee it! With minimal maintenance your Mereen-Johnson saw will provide glue joints for many years.

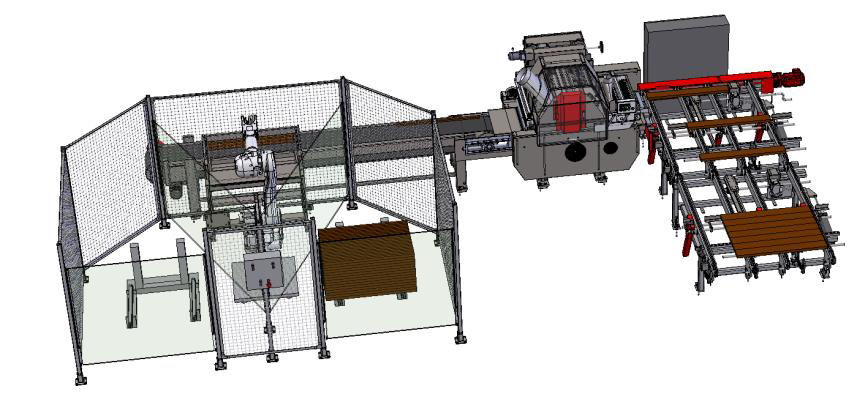

Automation & Robotics

Mereen-Johnson stands at the forefront of delivering cutting-edge automated handling solutions that will streamline your workforce and wood machinery assets. Our smart, automated handling solutions are meticulously crafted to enhance your machine throughput and efficacy while substantially trimming your labor expenses.

Our complete spectrum of services ranges from conceptualization and design of production lines to installation, personnel training and ongoing maintenance, and we cater to a wide array of client requirements, offering both standardized system solutions and fully personalized options to suit your specific needs.

Vertically integrated manufacturing in the USA means we control every step of the process to deliver the performance and longevity that the industry has grown to expect from us.

Listening to your specific needs, we will adapt a standard machine or develop a fully custom solution, including automation and robotics, and manufacture it in-house.

Our state-of-the-art production space has room to build, test and prove large-scale design solutions. Design-build teams work together to make your custom concept a reality.

We will always support your machine. From training programs to replacement parts, schematics to software support, we’ve got you covered, remotely or onsite.

The Model 110 Equalizer can be integrated with most moulders, creating a highly efficient…

Model 435 Series is a versatile line of machinery custom designed and manufactured for nea…

Mereen-Johnson’s CNC Dovetailers offer the quality construction, precision, reliability, a…

Feature the latest in technology advancements, ensuring improved consistency, accuracy, su…

For big shop performance at a small shop price. 12″ arbor capacity with up to two inboard…

The Mereen-Johnson 300 Series rip saws offer all the quality, heavy-duty construction, and…

With up to four moving saw blades, Select-Ripping has never been more affordable. Our 500…

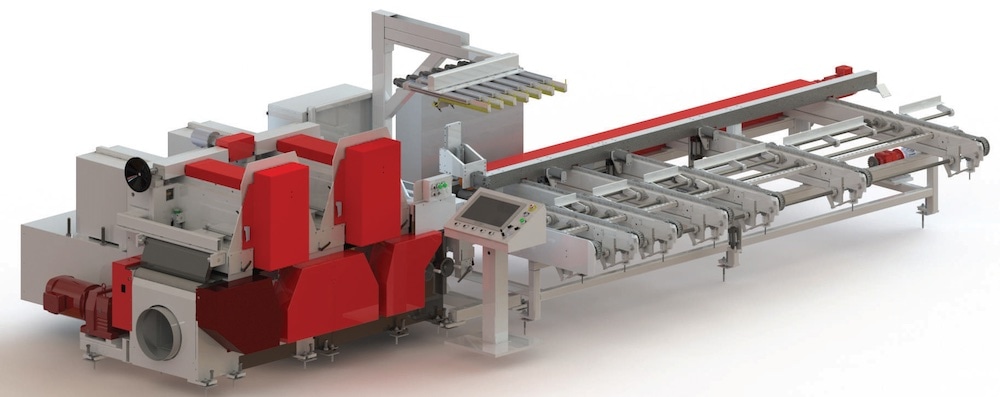

Mereen-Johnson manufacturers a complete line of gang rip saw infeed systems from manual to…

Perfect For High Production Operations, this machine is designed for high-production opera…

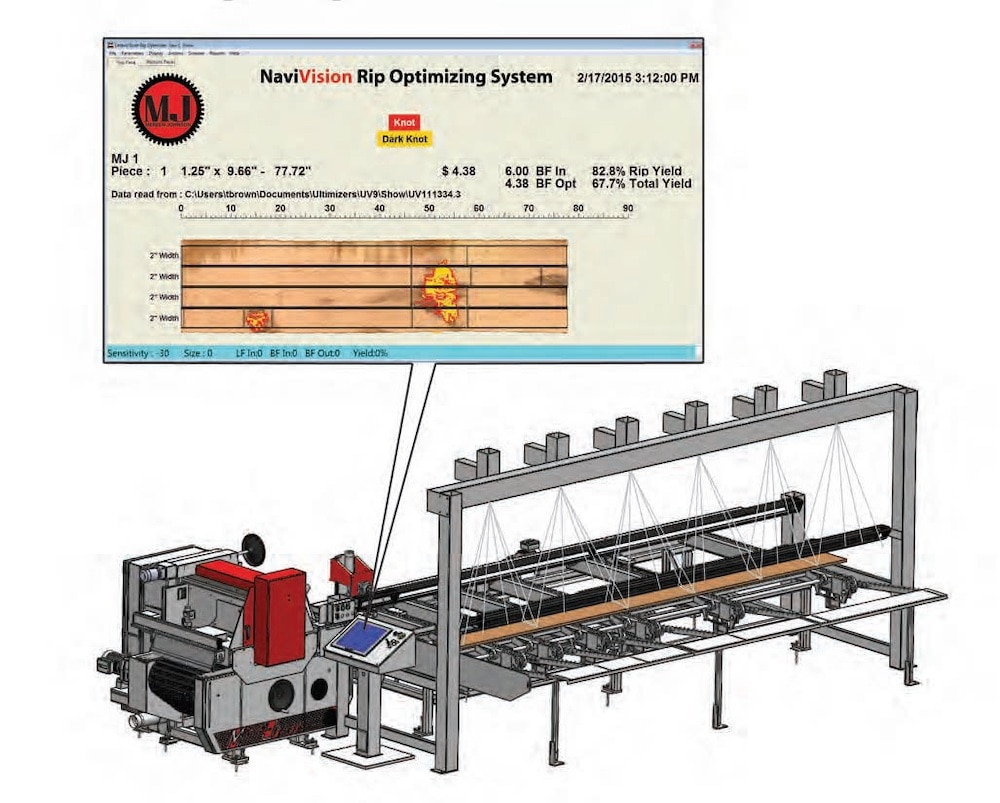

Now with NaviVision scanning, Mereen-Johnson provides multiple color cameras for single fa…

Our largest Rip Optimization system is the Scout; Equipped with infeed chains, board deale…

Our Roll Feed Saw’s high-speed, high-yield hogging arbor options virtually eliminates edgi…

Scout Loader is a fully automated feeder designed to directly offload deadpacked lumber fr…

Our Tenoners are designed for high production runs while simultaneously providing the flex…

The Diehl Machines MR-90 is an undercutting roll feed gang rip saw. The roll feed design r…

Diehl’s Full-Sized Rip Saw, a machine with the speed and performance to meet the most dema…

The Diehl Machines SL-35 is are our mid-sized Rip Saw, an economically priced machine with…