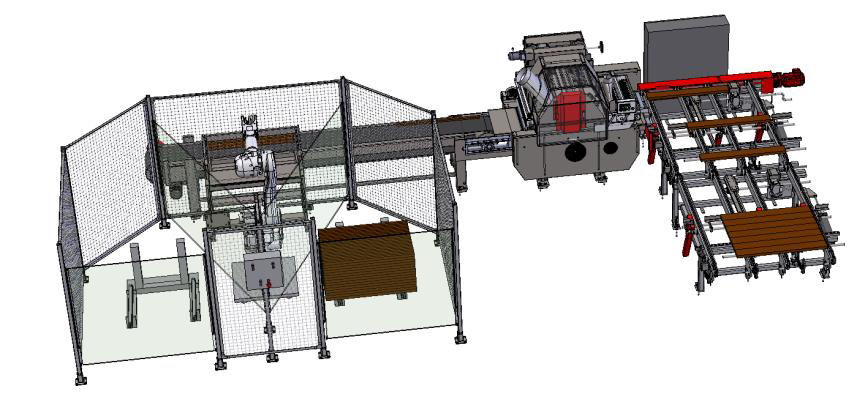

110 Equalizer

The Model 110 Equalizer can be integrated with most moulders, creating a highly efficient work cell to trim parts to length and then automatically feed the parts into your moulder.

Features

Precision and Efficiency Redefined

The Model 110 Equalizer will increase production, minimize material handling, reducing part damage potential, with less labor. The moulder / equalizer combination cell can be operated by one person for increased profits and productivity.

- Servo controlled feed belts with automatic electronic squaring adjust for the accuracy you need.

- Integral infeed adjustable hopper for consistent production flow.

- Integral outfeed transfer to moulder offers high production, even on short length parts.

- Stretcher mounted trim motor, feed belt and hold down with unit adjust for fast changeovers.

- Adjustable beam is mounted on linear bearings and equipped with electronic position control integrated with touch screen interface.

Specifications

| Capacity | 9” minimum, 96” maximum length capacity. 1/2” minimum to 2” maximum thickness capacity. |

| Trim Motors | 7-1/2” HP with variable frequency drive. |

| Feed System | Dual AC servo feed system provides feed rates of 8’ to 100’ per minute rate. |

| Interface | Touch Screen operator interface requires no special computer skills. |

Automation & Robotics

Tailored Solutions for the Solid Wood Sector

Mereen-Johnson stands at the forefront of delivering cutting-edge automated handling solutions that will streamline your workforce and wood machinery assets. Our smart, automated handling solutions are meticulously crafted to enhance your machine throughput and efficacy while substantially trimming your labor expenses.

Our complete spectrum of services ranges from conceptualization and design of production lines to installation, personnel training and ongoing maintenance, and we cater to a wide array of client requirements, offering both standardized system solutions and fully personalized options to suit your specific needs.

The Mereen-Johnson Difference

Made in the USA Quality

Vertically integrated manufacturing in the USA means we control every step of the process to deliver the performance and longevity that the industry has grown to expect from us.

Turnkey Custom Solutions

Listening to your specific needs, we will adapt a standard machine or develop a fully custom solution, including automation and robotics, and manufacture it in-house.

Excellence Under One Roof

Our state-of-the-art production space has room to build, test and prove large-scale design solutions. Design-build teams work together to make your custom concept a reality.

Parts, Service & Training

We will always support your machine. From training programs to replacement parts, schematics to software support, we’ve got you covered, remotely or onsite.