1101 Dovetailer

Mereen-Johnson’s CNC Dovetailers offer the quality construction, precision, reliability, and low cost of ownership you’ve come to expect from this industry leader.

Features

Precision, Reliability and Low Cost of Ownership

This unique machine offers production flexibility combined with lightning fast changeovers.

- 3HP high speed spindle motor.

- Variable speed spindle up to 20,000RPM

- Optional scoring pass to reduce tearout.

- Collet type tool change, increases flexibility with different types of bits/cutters.

- Automatic partial tenon removal (No special tools required).

- Able to Load multiple parts while spindle is in operation.

- Create half-blind dovetails and box joints.

- Change pitch, size and pattern of dovetail in seconds from operator console.

- Resharpened bits easily accommodated using cutter compensation.

- Tenon/mortise fit is easily adjusted from the operator console.

- Part thickness changeovers are made in seconds from the operator console.

- Programmable cutting speeds with high speed non-cutting moves between zones.

- Easy to understand and simple to use.

Specifications

| Capacity | Up to 13.5” high drawer (4 zone use), 28” high drawer (dual zone use) 3/8” to 3/4” material thickness 1-3/4” to 28” drawer height 6“ minimum drawer width 7” minimum drawer depth |

| Spindle | 3 HP High Speed Spindle Motor Collet type tool change system |

| Carriages | AC brushless servo motors Precision rack & roller pinion style drive. |

| Clamps | Manual pneumatic actuation |

| Interface | Touchscreen operator interface |

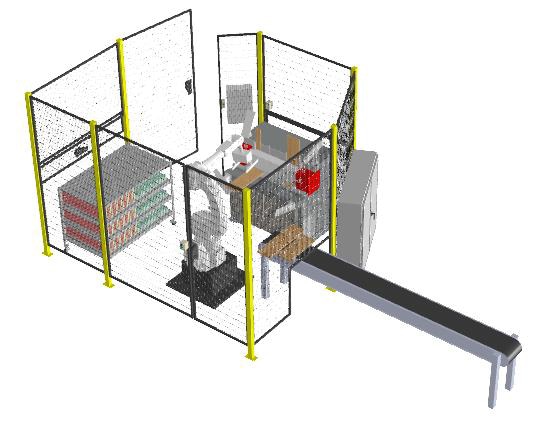

Automation & Robotics

Tailored Solutions for the Solid Wood Sector

Mereen-Johnson stands at the forefront of delivering cutting-edge automated handling solutions that will streamline your workforce and wood machinery assets. Our smart, automated handling solutions are meticulously crafted to enhance your machine throughput and efficacy while substantially trimming your labor expenses.

Our complete spectrum of services ranges from conceptualization and design of production lines to installation, personnel training and ongoing maintenance, and we cater to a wide array of client requirements, offering both standardized system solutions and fully personalized options to suit your specific needs.

The Mereen-Johnson Difference

Made in the USA Quality

Vertically integrated manufacturing in the USA means we control every step of the process to deliver the performance and longevity that the industry has grown to expect from us.

Turnkey Custom Solutions

Listening to your specific needs, we will adapt a standard machine or develop a fully custom solution, including automation and robotics, and manufacture it in-house.

Excellence Under One Roof

Our state-of-the-art production space has room to build, test and prove large-scale design solutions. Design-build teams work together to make your custom concept a reality.

Parts, Service & Training

We will always support your machine. From training programs to replacement parts, schematics to software support, we’ve got you covered, remotely or onsite.