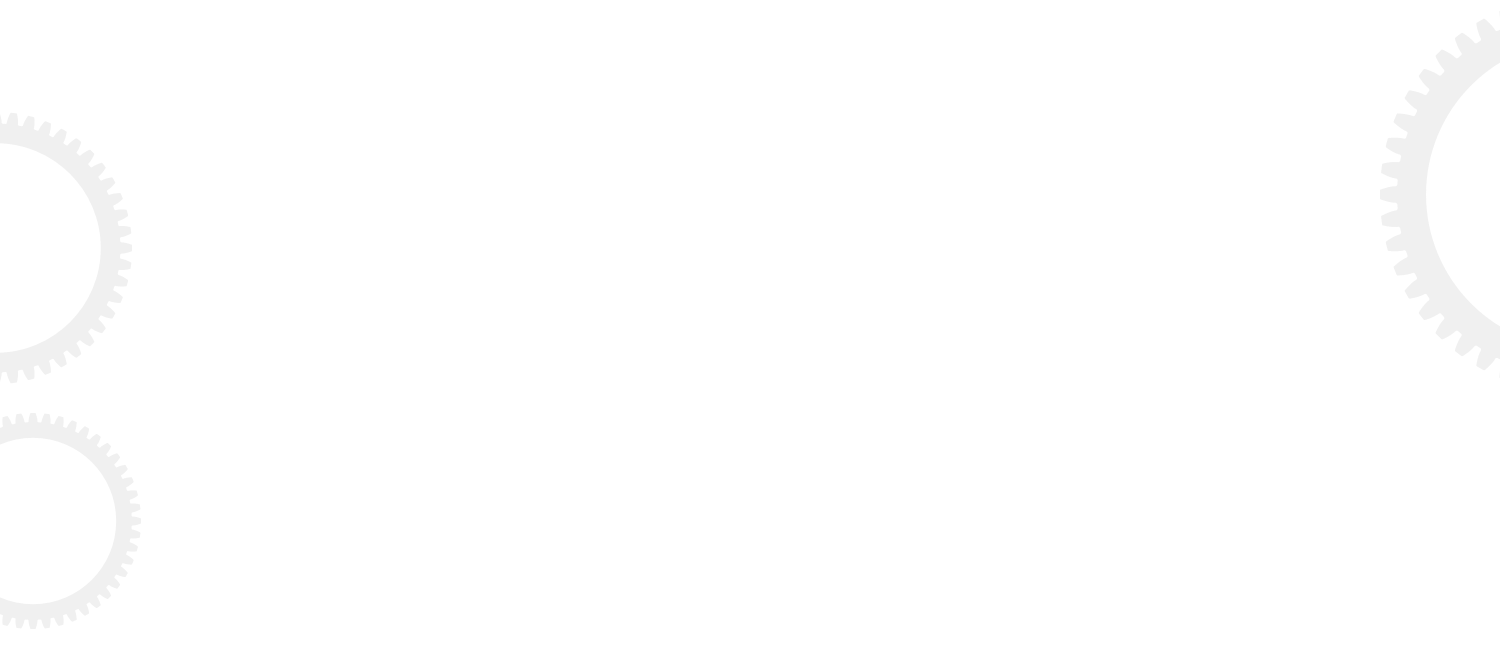

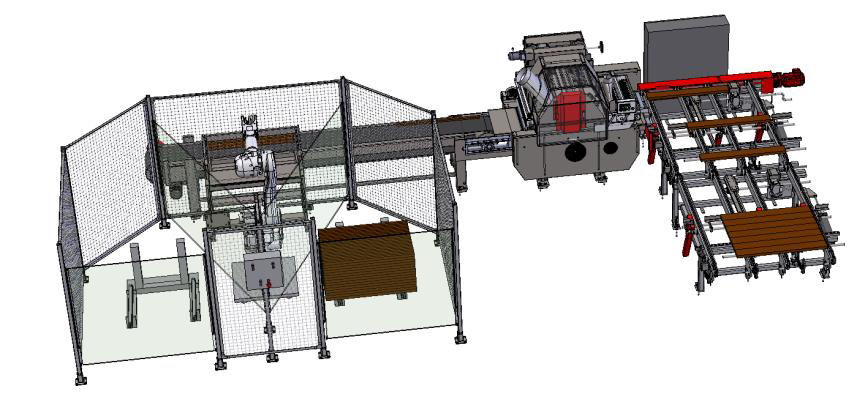

435 Panel Saw

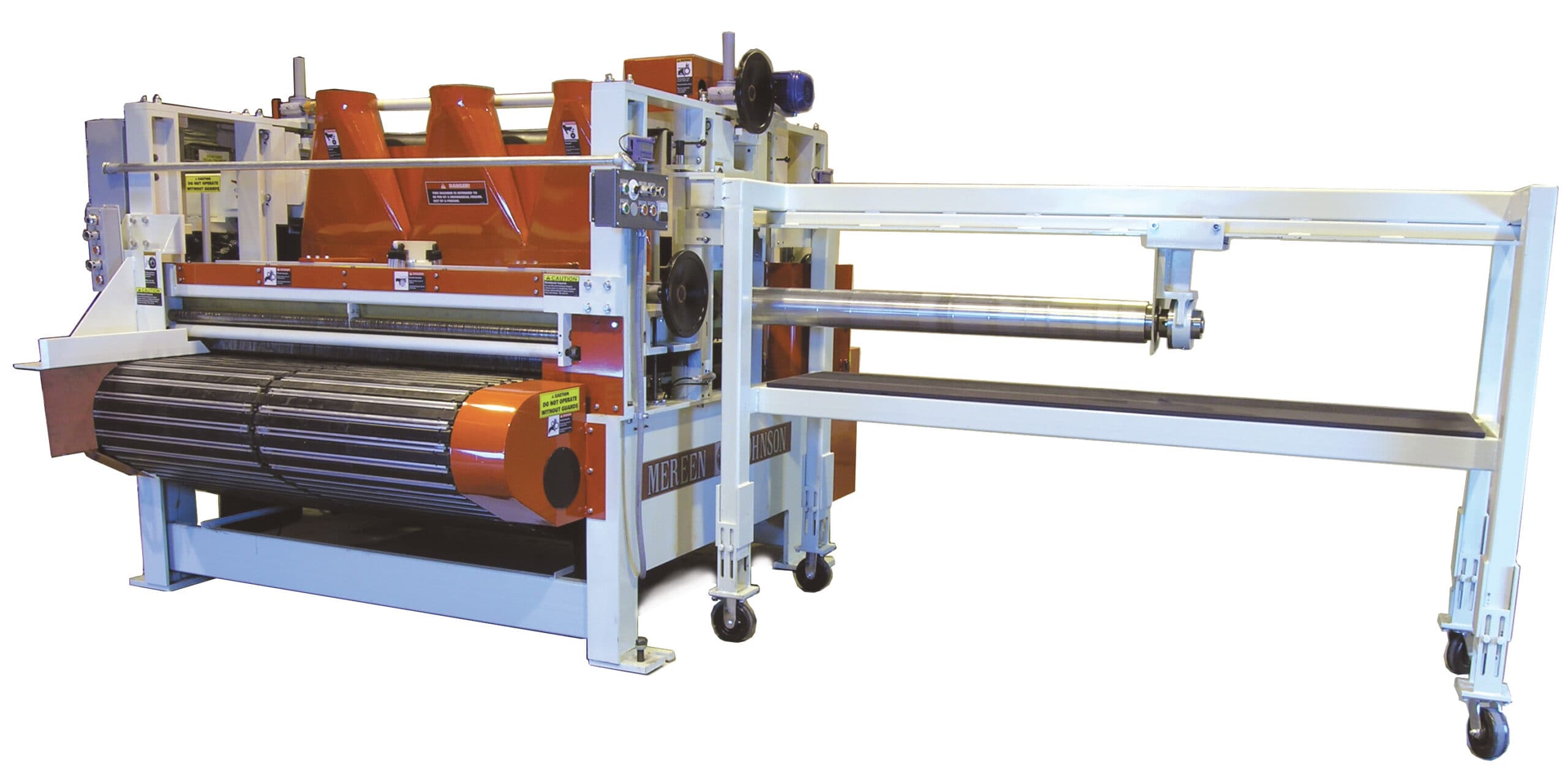

Model 435 Series is a versatile line of machinery custom designed and manufactured for nearly any high production ripping, cross cutting or sizing application.

Features

Custom Manufactured Equipment to Meet Your Individual Production Requirements

- Designed for the LVL, Plywood, Hardboard, OSB and Particleboard Industries.

- Available in Roll Feed systems for high speed applications with minimal maintenance, or Dip Chain and Chain Feed systems offering greater precision.

- Available with clamp-up arbors featuring quick change roll out design or individual motors with manual, powered, or CNC position setting.

- Flying Saws and Reciprocating Saws for cross cutting continuous flow and extruded product.

- Two pass systems with integral automatic corner transfers to maximize productivity.

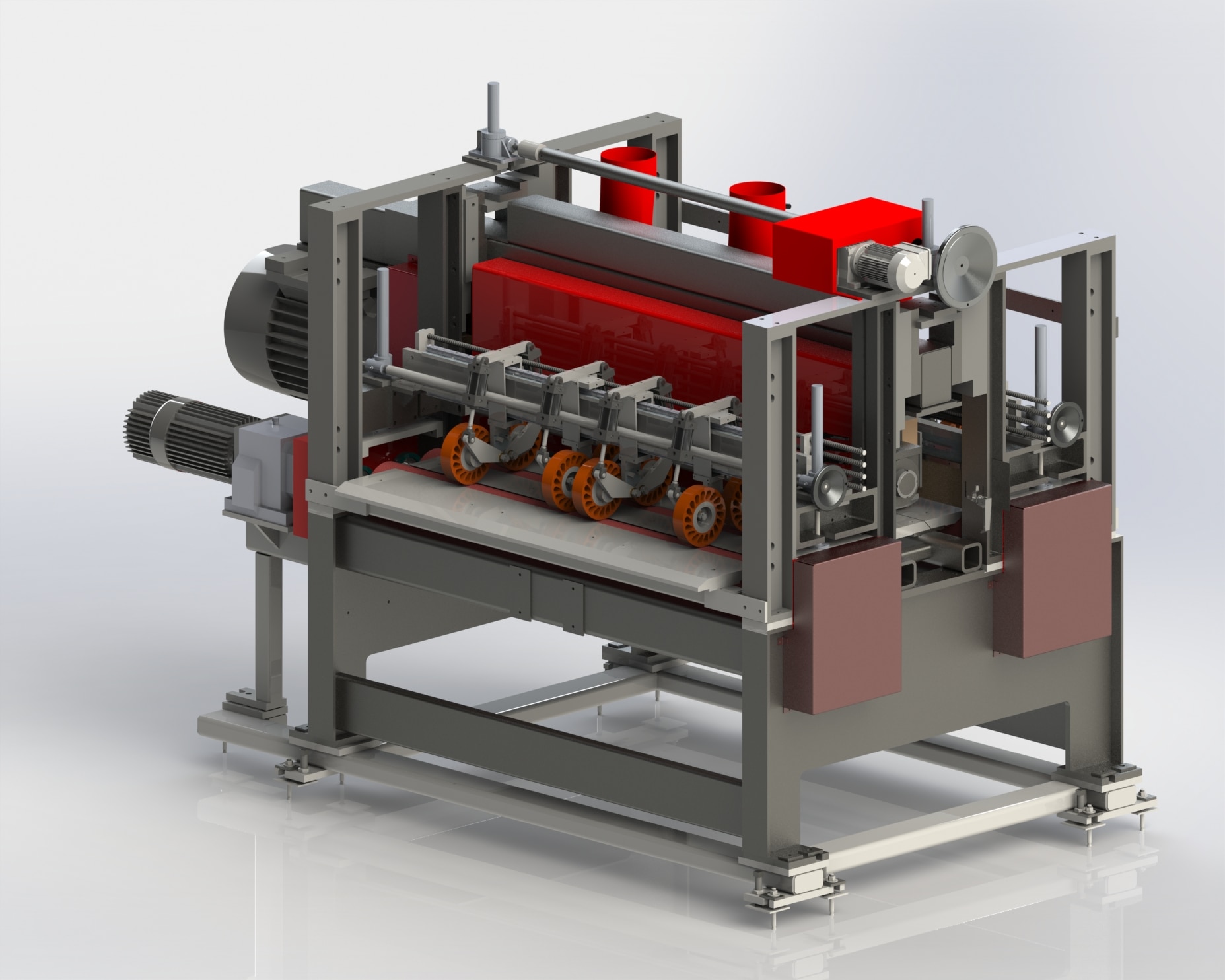

Automation & Robotics

Tailored Solutions for the Solid Wood Sector

Mereen-Johnson stands at the forefront of delivering cutting-edge automated handling solutions that will streamline your workforce and wood machinery assets. Our smart, automated handling solutions are meticulously crafted to enhance your machine throughput and efficacy while substantially trimming your labor expenses.

Our complete spectrum of services ranges from conceptualization and design of production lines to installation, personnel training and ongoing maintenance, and we cater to a wide array of client requirements, offering both standardized system solutions and fully personalized options to suit your specific needs.

The Mereen-Johnson Difference

Made in the USA Quality

Vertically integrated manufacturing in the USA means we control every step of the process to deliver the performance and longevity that the industry has grown to expect from us.

Turnkey Custom Solutions

Listening to your specific needs, we will adapt a standard machine or develop a fully custom solution, including automation and robotics, and manufacture it in-house.

Excellence Under One Roof

Our state-of-the-art production space has room to build, test and prove large-scale design solutions. Design-build teams work together to make your custom concept a reality.

Parts, Service & Training

We will always support your machine. From training programs to replacement parts, schematics to software support, we’ve got you covered, remotely or onsite.