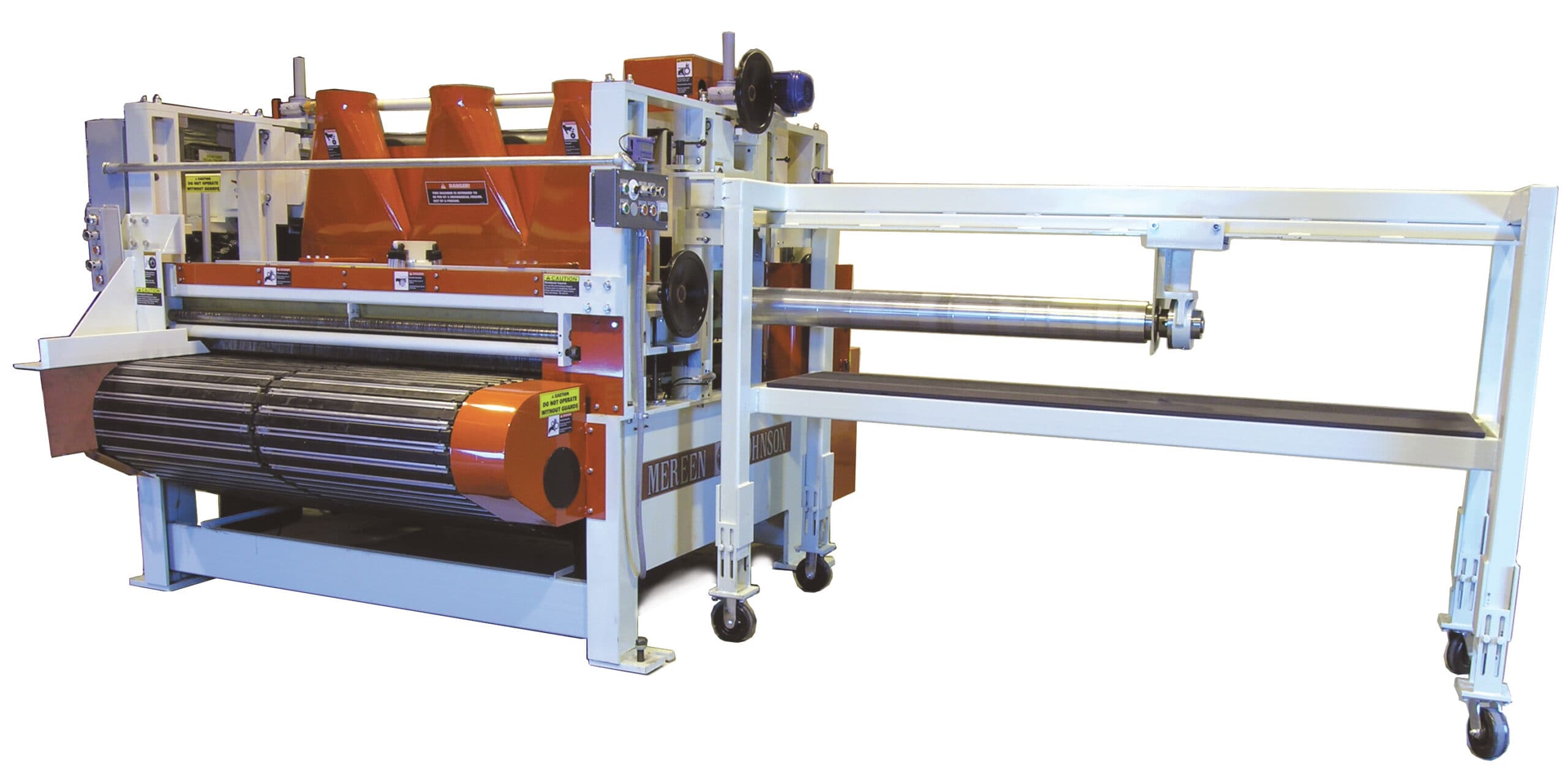

110 Equalizer

The Model 110 Equalizer can be integrated with most moulders, creating a highly efficient…

The Diehl Machines SL-35 is are our mid-sized Rip Saw, an economically priced machine with the speed and performance of large saws, with guaranteed glue line accuracy.

The Diehl Machines SL-30 is our most affordable Rip Saw with the same guaranteed glue line accuracy of our larger saws. All this coupled with our legendary quality and durability.

Specifications

Over 85 years of rip saw manufacturing experience has been put to use developing the SL series of straight line rip saws. The SL-35 features a 15 HP arbor motor, vertical arbor adjustment, and a 2 HP variable speed drive that gives the capacity for higher feed speeds.

Diehl’s proven chain/race, spindle/arbor and pressure roll system make up the foundation for this saw that produces the industry’s most accurate glue line cut, guaranteed. The Diehl SL-35 is the rip saw that you can depend on for continuous quality performance.

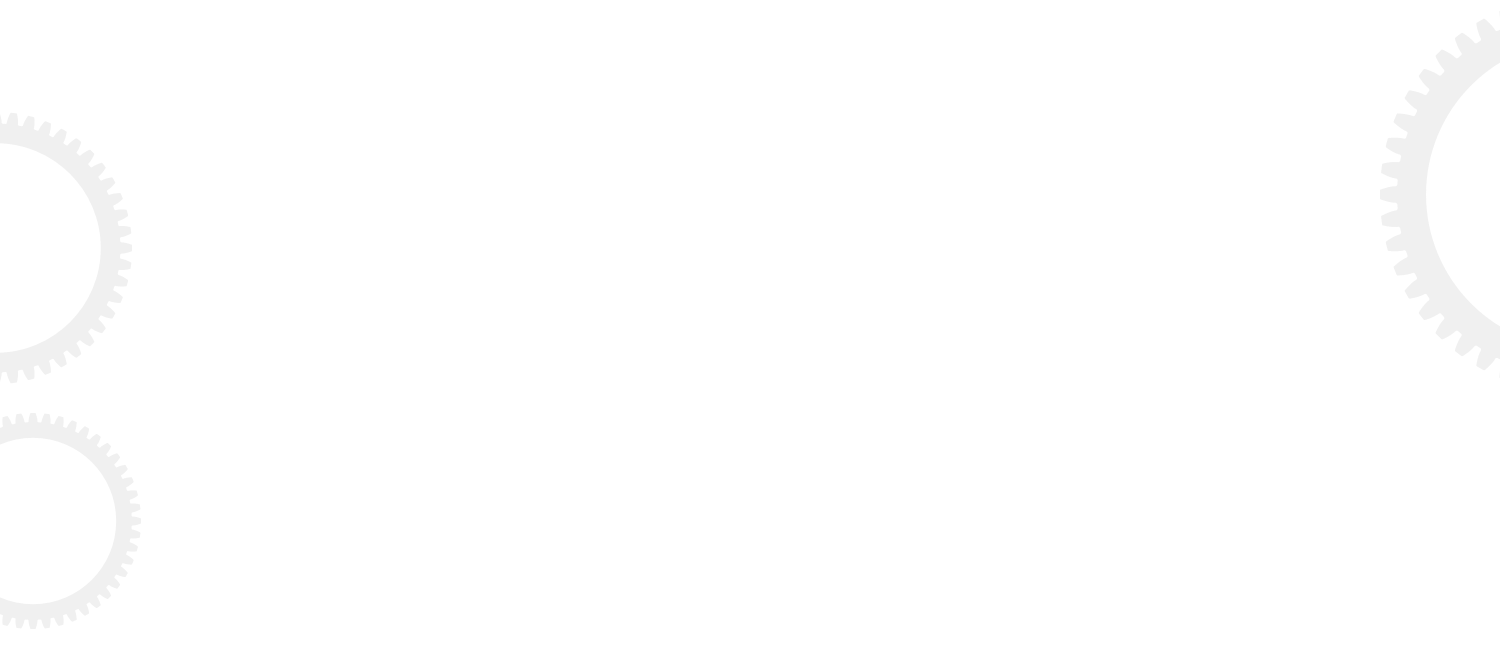

The front view illustrates access into the electrically interlocked saw pit area, the dual anti-kickback finger, system the pivoting pressure beam side guard and the adjustment handwheel to accommodate correct positioning of the saw blade for varying thicknesses of material.

The machine’s back side is shown with the arbor drive housing cover removed to depict the automatic arbor brake.

Optional Add-On

The system allows the operator to easily program a cutting list of multiple widths with the touch screen. It then calculates the best possible yield from each board, automatically positions the guide before each cut and tallies the cut piece against the cutting list to eliminate over production.

Optional Add-on

Automatic raising and lowering of the lower kickback fingers is available as an option on all Diehl rip saws, and is especially recommended for operations where shorter stock is being processed. The feature provides two alternative methods to sense stock presence and lower the fingers below the worktable for easier and faster feeding.

To momentarily drop the lower kickback fingers for lateral positioning and feeding, stock may either be passed over a table sensor or brought into direct contact with the fingers.

Then, as the stock is being fed into the machine, feed roll sensors determine that the piece is securely held and allow the fingers not being held down by the stock to return above the table.

This entire lowering and raising of fingers not held down by the stock takes place before the material makes contact with the blade, insuring that a safe environment is maintained by the dual anti-kickback finger system.

Any fingers held down by the stock as it enters will automatically return to their up position as the trailing edge passes through the fingers.

Optional Add-on

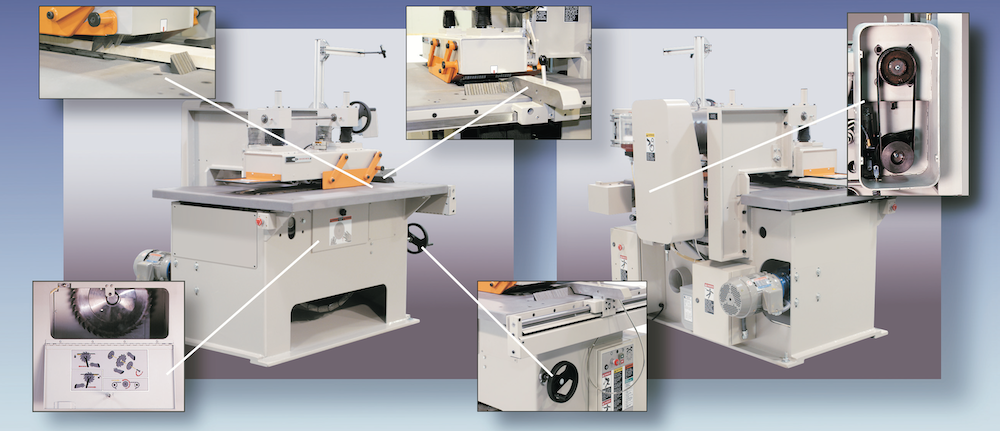

Adding a Diehl Machines Return Conveyor to a straight-line rip saw is a strategic move that can bring multiple operational benefits, from increasing productivity and improving safety to optimizing workflow and reducing costs. The investment in a return conveyor can pay off quickly by enhancing the efficiency and profitability of woodworking operations.

Automation & Robotics

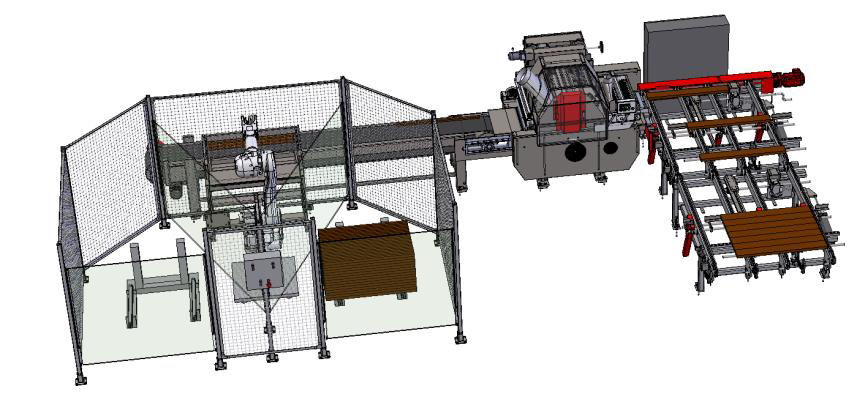

Mereen-Johnson stands at the forefront of delivering cutting-edge automated handling solutions that will streamline your workforce and wood machinery assets. Our smart, automated handling solutions are meticulously crafted to enhance your machine throughput and efficacy while substantially trimming your labor expenses.

Our complete spectrum of services ranges from conceptualization and design of production lines to installation, personnel training and ongoing maintenance, and we cater to a wide array of client requirements, offering both standardized system solutions and fully personalized options to suit your specific needs.

Vertically integrated manufacturing in the USA means we control every step of the process to deliver the performance and longevity that the industry has grown to expect from us.

Listening to your specific needs, we will adapt a standard machine or develop a fully custom solution, including automation and robotics, and manufacture it in-house.

Our state-of-the-art production space has room to build, test and prove large-scale design solutions. Design-build teams work together to make your custom concept a reality.

We will always support your machine. From training programs to replacement parts, schematics to software support, we’ve got you covered, remotely or onsite.

The Model 110 Equalizer can be integrated with most moulders, creating a highly efficient…

Model 435 Series is a versatile line of machinery custom designed and manufactured for nea…

Mereen-Johnson’s CNC Dovetailers offer the quality construction, precision, reliability, a…

Perfect For High Production Operations, this machine is designed for high-production opera…

For big shop performance at a small shop price. 12″ arbor capacity with up to two inboard…

The Mereen-Johnson 300 Series rip saws offer all the quality, heavy-duty construction, and…

Mereen-Johnson Multiple Rip Saws offer straight line precision gang ripping with glue join…

With up to four moving saw blades, Select-Ripping has never been more affordable. Our 500…

Mereen-Johnson manufacturers a complete line of gang rip saw infeed systems from manual to…

Feature the latest in technology advancements, ensuring improved consistency, accuracy, su…

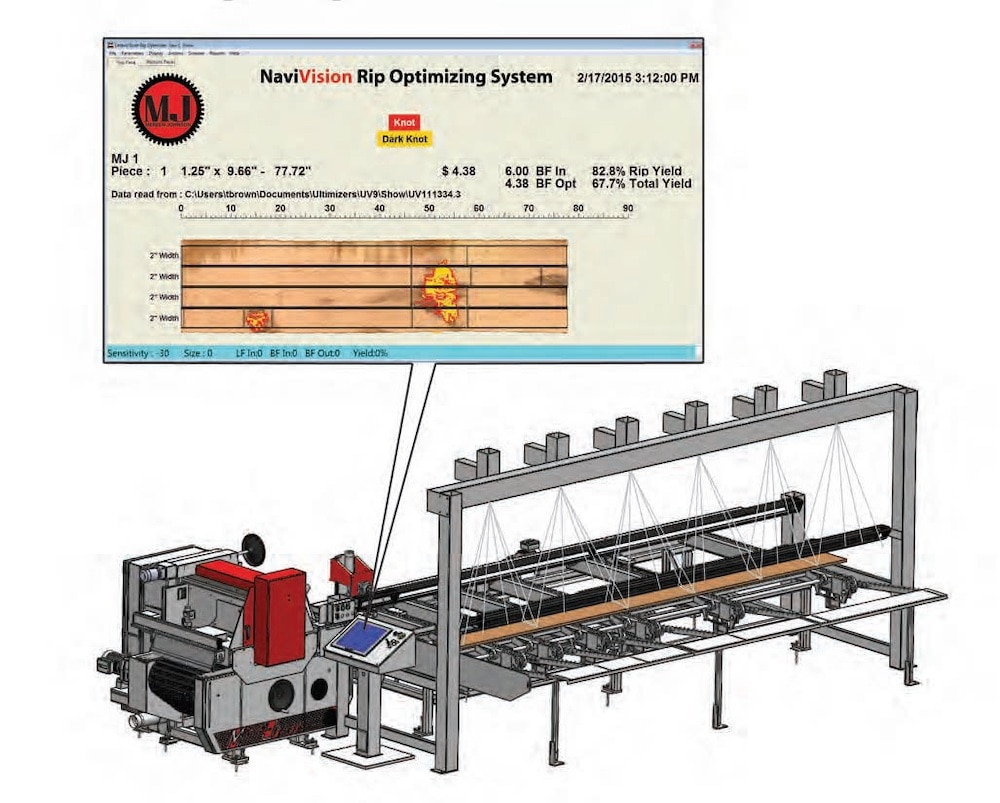

Now with NaviVision scanning, Mereen-Johnson provides multiple color cameras for single fa…

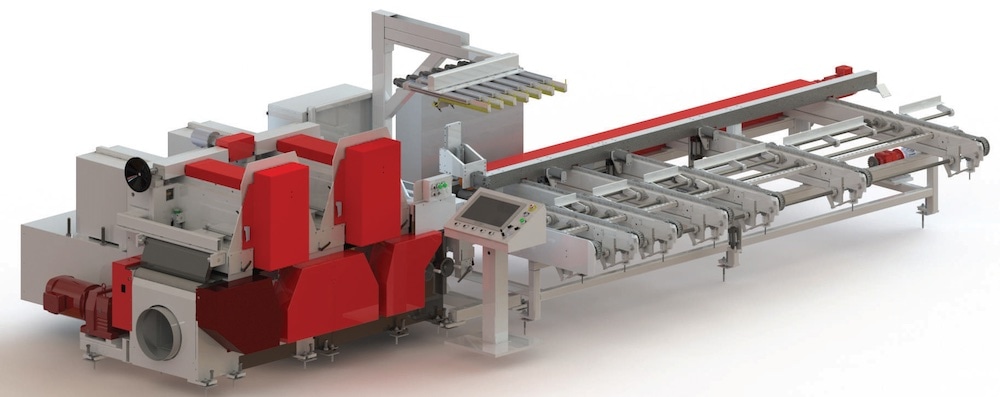

Our largest Rip Optimization system is the Scout; Equipped with infeed chains, board deale…

Our Roll Feed Saw’s high-speed, high-yield hogging arbor options virtually eliminates edgi…

Scout Loader is a fully automated feeder designed to directly offload deadpacked lumber fr…

Our Tenoners are designed for high production runs while simultaneously providing the flex…

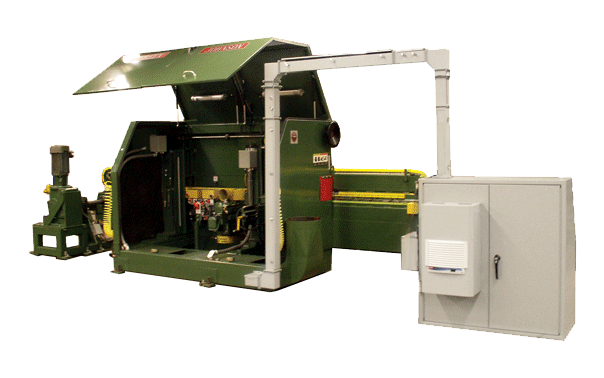

The Diehl Machines MR-90 is an undercutting roll feed gang rip saw. The roll feed design r…

Diehl’s Full-Sized Rip Saw, a machine with the speed and performance to meet the most dema…