Rip Navigator Scout

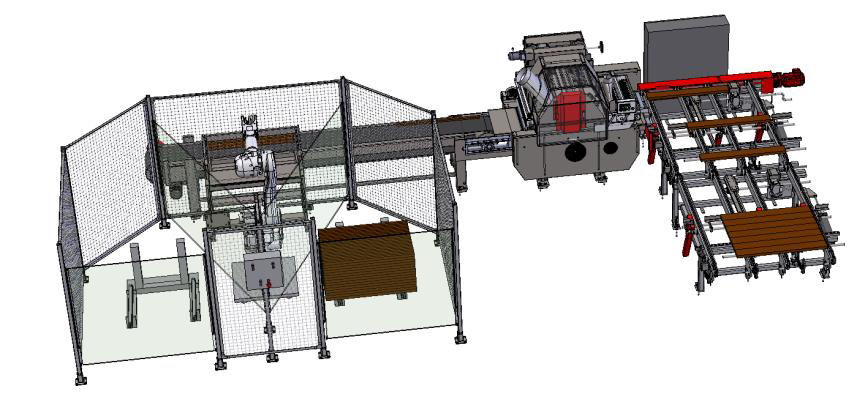

Our largest Rip Optimization system is the Scout; Equipped with infeed chains, board deale…

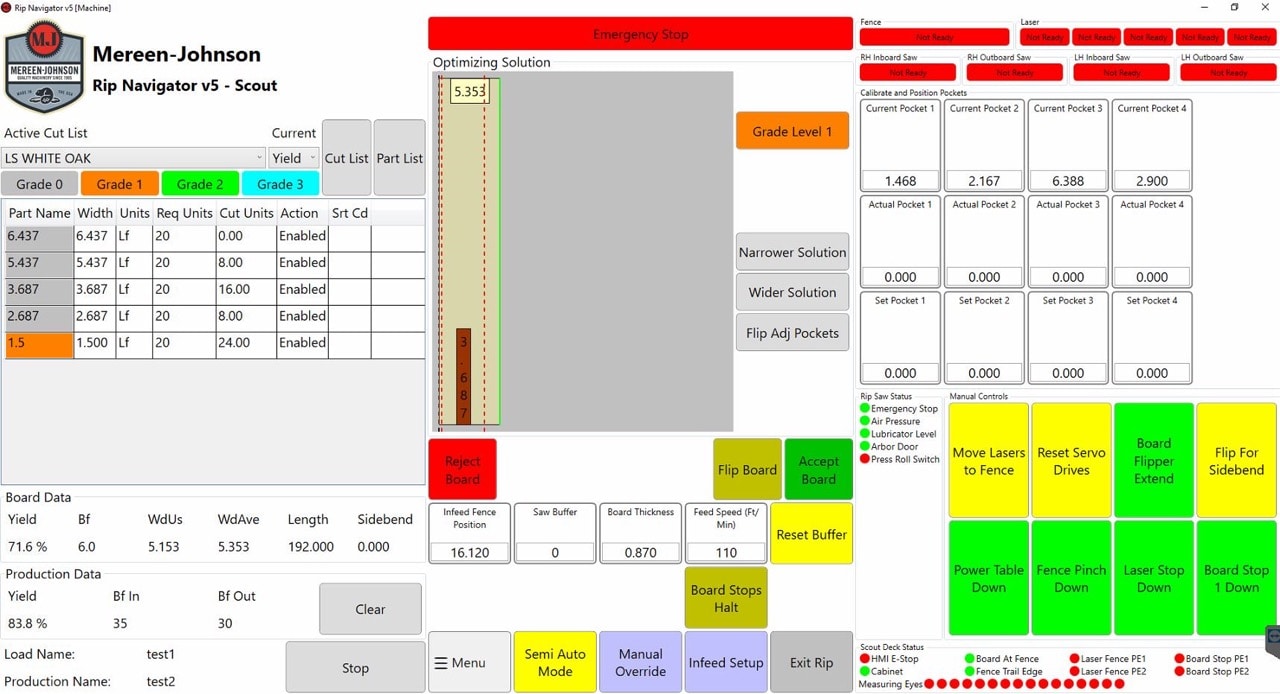

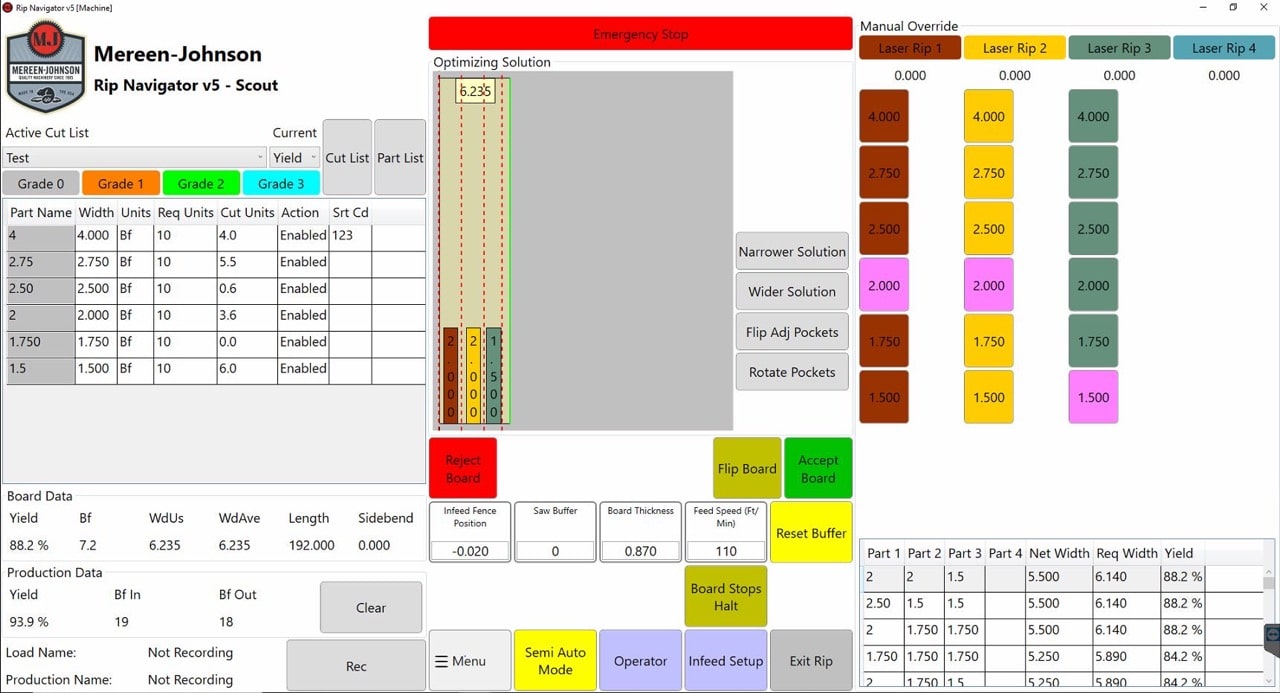

Our rip optimizing systems are designed to increase production, improve yield and reduce the need for re-ripping or other downstream interventions. By scanning each board and instantly generating the ideal rip solution for it based on width, length, defects and other factors, our systems streamline your production, reduce waste, improve feeding accuracy and enhance operator safety. No special computer or programming skills are needed. Production reporting is detailed and customizable.

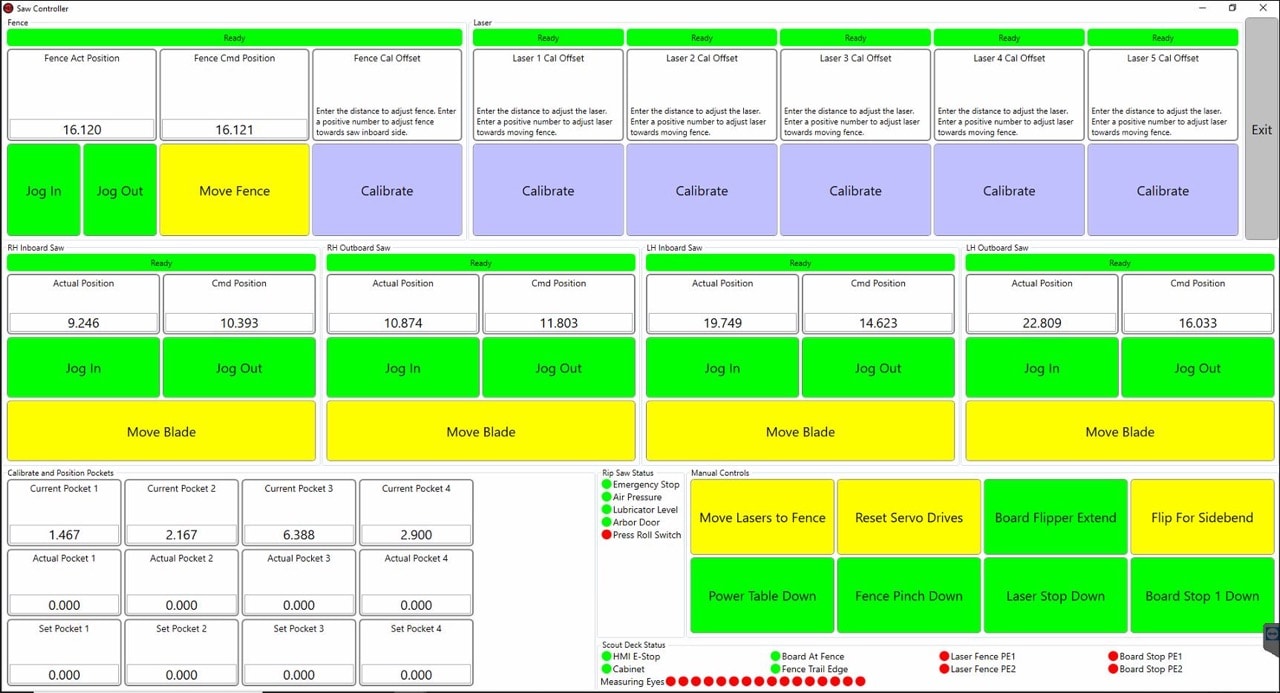

Our newly enhanced Rip Navigator 5.0 technology has three modes of operation to provide production flexibility: Yield Mode to maximize fiber recovery, Value Mode that allows you to quantify a dollar value for needed components, and Manual Mode for times when inventory is more important than yield recovery. With optional board flipping and other features, these systems integrate seamlessly with Mereen-Johnson rip saws and other material handling equipment. An optional NaviVision upgrade further enhances scanning with multiple color cameras.

Our new service-based architecture allows for “Remote Cut List” entry, keep your line running. It also allows for better cut list control and real time monitoring (at the machine or remotely) with options for more reporting features. It will allow the use handheld devices for cut list entry (phone, tablet).

Machines

Our largest Rip Optimization system is the Scout; Equipped with infeed chains, board deale…

For big shop performance at a small shop price. 12″ arbor capacity with up to two inboard…

Automation & Robotics

Mereen-Johnson stands at the forefront of delivering cutting-edge automated handling solutions that will streamline your workforce and wood machinery assets. Our smart, automated handling solutions are meticulously crafted to enhance your machine throughput and efficacy while substantially trimming your labor expenses.

Our complete spectrum of services ranges from conceptualization and design of production lines to installation, personnel training and ongoing maintenance, and we cater to a wide array of client requirements, offering both standardized system solutions and fully personalized options to suit your specific needs.